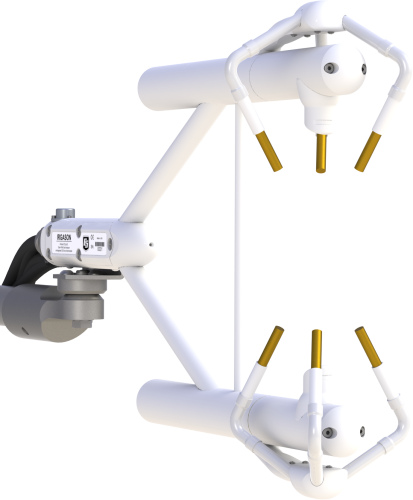

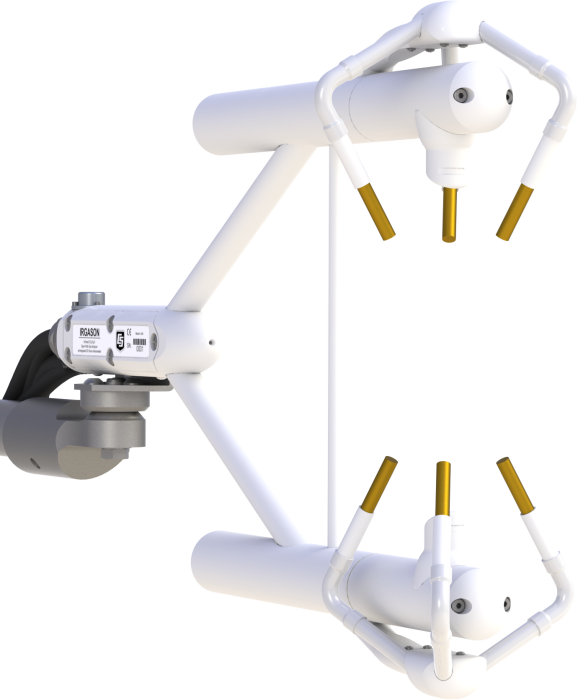

ガスアナライザと超音波風速計を1つのセンサに統合

概要

コロケーション測定の利点については、ポスター「オープンパスガスアナライザと超音波風速計のコロケーションによる渦相関法フラックス測定の改善」を参照してください。

続きを読む利点と特徴

- コンフォーマルコーティングにより、腐食環境下でも音波振動子を保護

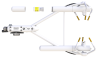

- 2つのセンサを別々に使用するよりも流れの歪みが少ない支持構造

- ガス分析計と音波風速計を完全に同位置に配置することで、センサの分離による流束損失を回避

- ガス分析計と音波風速計の測定が同期しているため、タイムラグを補正する必要がない

- 低消費電力、太陽光発電アプリケーションに最適

- アクティブな熱制御なしで温度補償された測定が可能

- 低ノイズ

- 最大出力レート60Hz、帯域幅20Hz

- 角度のついた窓が水を排出し、窓の汚れに強い

- 現場での耐久性

- フィールドサービス可能

- CO2、H2O、圧力、温度の広い範囲で、実際に使用されるすべての組み合わせで工場校正済み

- 豊富な診断パラメータ

- Campbell Scientific社製データロガーとの完全な互換性:現場での設定、構成、現場でのゼロとスパンは、データロガーから直接可能

- 音波温度は3つの音響経路から決定:横風の影響を補正

- 革新的な信号処理と変換器ウィックにより、降雨時の風速計の性能を大幅に向上

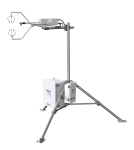

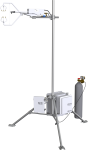

イメージ

詳細

- Ux (m/s)

- Uy (m/s)

- Uz (m/s)

- 音波温度 (°C)

- 音波診断

- CO2 密度 (mg/m3)

- H2O 密度 (g/m3)

- ガスアナライザ診断

- 周囲温度 (°C)

- 大気圧 (kPa)

- CO2 信号強度

- H2O 信号強度

- ソース温度 (°C)

仕様

| 特許 | 米国特許第D680455号 |

| 動作温度範囲 | -30° ~ +50°C |

| 校正圧力範囲 | 70 ~ 106 kPa |

| 入力電圧範囲 | 10 ~ 16 Vdc |

| 消費電力 | 5 W (定常状態および電源投入時)25°C |

| 測定レート | 60 Hz |

| 出力帯域幅 | 5, 10, 12.5, 20 Hz (ユーザーによるプログラム設定可能) |

| 出力オプション | SDM, RS-485, USB, アナログ (CO2 及び H2O only) |

| 補助入力 | 気温と気圧 |

| 保証 | 3年間または17,500時間の稼働 (いずれか早い方) |

| ケーブル長さ | 3 m (10 ft) IRGASON® から EC100まで |

| 重さ |

|

ガスアナライザ |

|

| パスの長さ |

15.37 cm (6.05 in.) 質量密度を濃度に変換するために、温度 20°C および圧力 101.325 kPa が使用されました。 |

ガスアナライザ - CO2 パフォーマンス |

|

| -注意- | 質量密度を濃度に変換するために、温度 20°C および圧力 101.325 kPaを使用しました。 |

| 正確度 |

|

| 精密RMS(最大) | 0.2 mg/m3 (0.15 μmol/mol) 精度検証試験の公称条件:25℃、86 kPa、400 μmol/mol CO22、露点温度12℃、帯域幅20 Hz。 |

| 校正レンジ | 0 ~ 1,000 μmol/mol (ご要望に応じて0~3,000μmol/molまで対応可能)。 |

| 温度によるゼロ・ドリフト(最大) | ±0.55 mg/m3/°C (±0.3 μmol/mol/°C) |

| 温度によるゲイン・ドリフト(最大) | 読み取り値の±0.1%/°C |

| クロス感度(最大) | ±1.1 x 10-4 mol CO2/mol H2O |

ガスアナライザ - H2O パフォーマンス |

|

| -注意- | 質量密度を濃度に変換するために、温度 20°C および圧力 101.325 kPaを使用しました。 |

| 正確度 |

|

| 精密RMS(最大) |

0.004 g/m3 (0.006 mmol/mol) 精度検証試験の公称条件:25℃、86kPa、400μmol/mol CO2、露点温度12℃、帯域幅20Hz。 |

| 校正レンジ | 0 ~ 72 mmol/mol (露点温度38) |

| 温度によるゼロ・ドリフト(最大) | ±0.037 g/m3/°C (±0.05 mmol/mol/°C) |

| 温度によるゲイン・ドリフト(最大) | 読み取り値の±0.3%/°C |

| クロス感度(最大) | ±0.1 mol H2O/mol CO2 |

超音波風速計 - 正確度 |

|

| -注意- | 音速風速計の精度仕様は、風速<30 m s-1、風向角±170°です。 |

| オフセットエラー |

|

| ゲインエラー |

|

| 測定精度 RMS |

|

| 音速 | 3つの音響経路から決定 (横風の影響を補正) |

| 雨 | 革新的な信号処理とトランスデューサーウィックにより、降雨時の風速計の性能が大幅に向上します。 |

基本気圧計(オプション -BB) |

|

| 正確度 |

|

| 測定レート | 10 Hz |

強化気圧計(オプション -EB) |

|

| メーカー | Vaisala PTB110 |

| 正確度 | ±0.15 kPa (-30° ~ +50°C) |

| 測定レート | 1 Hz |

周囲温度 |

|

| メーカー | BetaTherm 100K6A1IA |

| 正確度 | ±0.15°C (-30° ~ +50°C) |

ドキュメント

マニュアル

テクニカルペーパー

コンプライアンス

その他

- Improved Flux Measurements from Campbell Scientific Open-Path Gas Analyzers: Utilizing Sonic Temperature to Account for Spectroscopic Effects on CO2 Density

- High-Frequency Air-Temperature Fluctuations for Spectroscopic Corrections

- Influence of Open-path Gas Analyzer Flow Distortion on Ultrasonic Wind Measurements

- Benefits of Having a Co-Located Measurement

- Using Molecular Sieve to Zero Infrared Gas Analyzers for Eddy Covariance or Atmospheric Profile Measurements

- Qingyuan Project Update

- IRGASON and EC150 Source and Detector Cover Updates

ダウンロード

EasyFlux DL for CR6OP v.2.01 (98.2 KB) 21-07-2022

CR6 datalogger program for Campbell open-path eddy-covariance systems.

EC100 OS v.8.02 (560 KB) 14-10-2019

EC100 Operating System.

Watch the Video Tutorial: Updating the EC100 Operating System.

ECMon v.1.6 (10.7 MB) 29-03-2016

EC100-Series Support Software.

Device Configuration Utility v.2.32.01 (47.7 MB) 15-04-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

EasyFlux DL for CR1000XOP v.2.01 (98.2 KB) 21-07-2022

CR1000X datalogger program for Campbell open-path eddy-covariance systems.

よくある質問

IRGASONに関するよくある質問の数: 22

すべて展開すべて折りたたむ

-

はい。FW05 などの細線熱電対を使用できます。

-

EC150 および IRGASON® ガス分析装置のウィンドウは、表面に水が溜まらないように研磨され、斜めに傾けられ、疎水性材料でコーティングされています。また、毛細管現象を促進し、ウィンドウの端から水を遠ざけるために、ウィンドウにウィックを使用することもできます。また、スナウトのヒーターをオンにして、降雨や結露によるデータ損失を最小限に抑えることもできます。

-

IRGASON® または EC150 と CSAT3A の電力要件は、電源投入時または定常動作時にかかわらず、室温で 5 W です。極端に低温または高温の場合、電力要件は 6 W に達します。

-

工場出荷時の校正では、CO2 および H2O 信号強度は 0.7 まで考慮されます。したがって、データの品質を確保するには、信号強度が 0.7 未満に低下する前にウィンドウをクリーニングする必要があります。

-

どの気圧計を使用するかはユーザーが選択します。気圧計の精度レベルとコストには直接的な相関関係があります。

- 基本的な気圧計の正確度は、0° ~ 50°C の範囲で ±1.5 kPa です。0° 未満では、誤差は直線的に増加し、-30°C では ±3.7 kPa になります。

- 高精度気圧計は、±0.15 kPa (-30° ~ +50°C) の正確度を提供します。

気圧計を選択するときは、圧力精度がフラックス計算に与える影響を考慮してください。顕熱フラックスの場合、気圧は空気の密度を計算するために使用され、それが顕熱フラックスを直接スケーリングします。したがって、気圧の測定値が 1% ずれると、顕熱フラックスも 1% ずれます。

CO2 フラックスについては、EC150 と IRGASON® は CO2 を密度として報告します。したがって、気圧はフラックスの直接計算には使用されません。ただし、圧力測定の誤差により、CO2 スパンから生じる CO2 フラックスに誤差が生じる可能性があります。スパン手順中に、ユーザーは「真の CO2 値」を CO2 濃度として入力し、後で気圧を使用して密度に変換します。その結果、CO2 測定の誤差は気圧測定の誤差に正比例します。

-

IRGASON® は、ほとんどの陸上用途に最適化されています。IRGASON® を海洋環境または腐食性化学物質 (ブドウ栽培における硫黄含有化合物など) にさらされる環境で使用する場合は、内陸の化学物質のない環境に配置されたユニットよりも、音響トランスデューサーの劣化が早くなり、交換が必要になることを想定してください。可能であれば、塩水のしぶきや飛沫、腐食性化学物質への曝露を減らす方法で IRGASON® を取り付けてください。

-

IRGASON® と EC150 は工場で温度範囲 (-30° ~ +50°C) と気圧範囲 (70 ~ 106 kPa) にわたって校正されているため、気圧計と温度センサが必要です。

-

IRGASON® は一体型のオープンパスガス分析装置とソニック風速計ですが、EC150 は CSAT3A ソニック風速計と組み合わせることができる独立したオープンパスガス分析装置です。どちらの機器も同期または同時測定を提供しますが、これは 1 セットの電子機器である EC100 がガスと風の両方の測定の実行を制御することによって可能になります。統合設計の IRGASON® は、測定を正確に同じ場所で行うことができます。つまり、フラックスに空間補正を適用する必要がありません。IRGASON® とは異なり、EC150 の測定ボリュームはわずかに離れているため、空間補正を適用する必要があります。

詳細については、ホワイト ペーパー「EC150、IRGASON、または EC155: どの CO2 および H2O 渦共分散システムが私のアプリケーションに最適ですか?」を参照してください。

-

ゼロ/スパン調整を行う頻度は、現場の状況に大きく依存しますが、ゼロ/スパン調整を月に 1 回行うのがよい出発点です。一般的なガイドラインとして、時間の経過に伴う機器の光学ドリフトを監視して、ゼロ/スパン調整手順を実行する頻度を決定します。

-

工場の再校正は必要に応じて行われます。診断フラグが表示され始め、分析装置をクリーニングして設定を確認した後も消えない場合は、再校正が必要です。さらに、分析装置のパフォーマンスが低下している場合は、再校正をお勧めします。

パフォーマンス テストの 1 つは、1 年間の絶対信号強度ドリフトをチェックすることです。1 年に数パーセントのドリフトは正常です。年間の信号強度ドリフトが過度の場合、またはウィンドウがきれいなときに信号強度が 0.7 を下回る場合は、工場の再校正が必要です。さらに、CO2 と H2O の信号強度の比率が 1 に近くない場合も、工場の再校正の時期である可能性があります。

ケーススタディ

概要 気候変動との戦いにおいて、大気中の温室効果ガス濃度の上昇という地球規模の課題に対処するための革新的な解決策が生まれています。英国生態学・水文学センター (UKCEH) は、アベリストウィス大学などと提携して、この研究の最前線に立っています。Campbell Scientific社の最先端の渦相関システムを使用して、UKCEH はさまざまな作物による CO2 吸収を監視するプロジェクトを先導しており、主に多用途のススキ (エレファント グラス) に焦点を当てています。 課題 大気中の温室効果ガス濃度の上昇という差し迫った問題に対処するには、その地球温暖化への影響を総合的に理解し、その影響を緩和する必要があります。課題は、エネルギー安全保障と農村経済を維持しながら、大気中の CO2 濃度の削減に積極的に貢献する持続可能な解決策を見つけることです。 解決策 UKCEH は、キャンベル サイエンティフィック社の高度な渦相関システムを導入し、作物による大気中の CO2......続きを読む

ユタ州地質調査所は、ユタ州水利権局の支援を受けて、ユタ州全域に蒸発散量を測定するための渦相関観測所のネットワークを構築しました。これらの観測所は、陸地からの水の蒸発と植物による水の蒸散を合わせた量を測定します。消費的使用、つまり植物によって吸収され蒸散される水は、耕作地を含む植生地帯の蒸発散に大きく貢献します。 ユタ州の水管理者が農業活動によって節約または使用される水を正確に判断するには、同州における水使用の地上測定の改善が不可欠です。ユタ フラックス ネットワーク (UFN) の目的は 2 つあります。1 つは、渦共分散法を使用してフィールドでの蒸発散量を測定し、そのデータを衛星で収集した測定値と比較することです。この目的のため、UFN はこれまでに 4 つの渦共分散ステーションを設置しており、今後もさらに設置する予定です。 これらのステーションは、研究グレードの計測機器のコア セットから構築されています。各ステーションには次のものが含まれます。 データロガー(CR1000XまたはCR6) 統合型音波風速計付きガス分析装置 (IRGASON) 温度および相対湿度プローブ(EE181-L) 4ウェイネットラジオメーター(NR01-L) 土壌熱流計(HFP01-L) 土壌温度センサー(TCAV-L) 土壌水分センサー(CS655およびSoilVue™10) 機械式風速計と風向計 光合成有効放射線(PAR)センサー 太陽光発電システム 各観測所は、観測所の風上地域に出入りする水蒸気、CO2、エネルギーの動きを正確に測定します。純放射計と土壌センサーは、エネルギーバランスと土壌熱流束を研究するために使用されます。これらの機器はすべて非常に正確で、その多くは極めて高い速度で測定値を取得できます。 ユタ州サンファン郡の......続きを読む

ケンタッキー州ジェームズタウン近郊のウルフ クリーク ダムは、一部は普通のコンクリート水力発電ダムとして建設されましたが、大部分は土盛り堤防構造でした。1950 年に完成しましたが、20 年以内に深刻な貯水池浸出問題が起こりました。いくつかの修復プロジェクトで、ある程度の成功を収めて水の流れを止めましたが、近年、管理者はダムの浸出が再び増加していることを緊急事態とみなしました。 さらなる被害をもたらす浸出を遮断するため、2006 年に修復工事が開始されました。このプロジェクトには、大規模なグラウト注入プログラムと、それに続く約 1,000,000 平方フィートのコンクリート製ダイヤフラム壁の建設が含まれています。プロジェクトの監視および分析部分の一部として、米国陸軍工兵隊 (USACE) は、URS Corporation に自動データ収集システム (ADAS) の設計、インストール、および運用を委託しました。 ADAS は、堤防の水位......続きを読む

Privacy Policy Update

We've updated our privacy policy. 詳細はこちら

Cookie Consent

Update your cookie preferences. クッキーの設定を更新する