This product is no longer available and has been replaced by: CR350.

| 利用できるサービス | |

|---|---|

| 修理 | 対応 |

| キャリブレーション | 対応 |

| フリーサポート | 対応 |

概要

CR800 は、過酷な遠隔環境でスタンドアロン操作を行うために設計された、小型の研究用データロガーです。測定するセンサの数が少ない小規模構成向けです。各 CR800 はセンサからの入力を読み取り、通信周辺機器を介してデータを送信します。ほとんどのセンサと通信デバイスは互換性があります。複数の CR800 をネットワークとして構成することも、ユニットを個別に展開することもできます。

別のモデルである CR850 は CR800 に似ていますが、現場での制御用にキーボードとディスプレイ画面が内蔵されています。

続きを読む利点と特徴

- 理想的なアプリケーションには、風速プロファイリング、気象観測所、ETo/農業、空気質、土壌水分、水位/水位、養殖、車両テスト、時間領域反射率測定法、SCADA、水質などがあります

- CR800 と CR850 は設計がシンプルなので、プログラムや配線が簡単です。

- 「シリアル センサとデバイスとのシリアル通信は、I/O ポート ペアを介してサポートされます」

- パルス カウント、制御ポート、シリアル通信機能を拡張するカスタム ASIC チップが含まれています

- チャネル拡張周辺機器と互換性があり、システムを拡張できます

- PakBus、Modbus、SDI-12、および DNP3 プロトコルをサポート

- 通信デバイスを接続するための CS I/O ポートと RS-232 ポートの両方が含まれています

- ガス放電管 (GDT) 保護入力

- データロガーがバッテリ電源から切断されている間も正確な時間を維持するバッテリバックアップクロック

- セットアップに合わせて LoggerNet、PC400、または Short Cut を使用してプログラムします

イメージ

CAD ファイル:

詳細

CR800 は、プラスチック製の外装に収められた計測用電子機器と、統合された配線パネルで構成されています。このデータロガーは、外部キーボード/ディスプレイと電源を使用します。消費電力が低いため、CR800 はソーラー パネルで充電したバッテリで長時間動作し、AC 電源は不要です。CR800 は、主電源が 9.6 V を下回ると実行を一時停止し、不正確な計測の可能性を減らします。

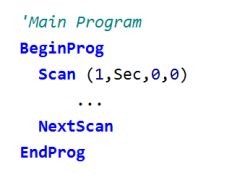

オンボード オペレーティング システムには、データロガーをプログラミングするための計測、処理、および出力命令が含まれています。プログラミング言語 CRBasic は、BASIC のような構文を使用します。ブリッジ構成、電圧出力、熱電対、およびパルス/周波数信号に固有の計測命令が含まれています。処理命令は、現場での処理のための代数、統計、および超越関数をサポートします。出力命令は、時間の経過に伴うデータを処理し、外部デバイスを制御します。

仕様

| -注意- | 注: 追加の仕様は、CR800 シリーズ仕様シートに記載されています。 |

| 動作温度範囲 |

|

| 最大スキャン速度 | 100 Hz |

| アナログ入力 | 6 つのシングルエンドまたは 3 つの差動 (個別設定可) |

| パルス カウンタ | 2 |

| 電圧励起端子 | 2 (VX1, VX2) |

| 通信ポート |

|

| スイッチ 12 ボルト | 1 つの端末 |

| デジタル I/O |

|

| 入力制限 | ±5 V |

| アナログ電圧精度 | ±(読み取り値の 0.06% + オフセット) 0°~40°C |

| ADC | 13 ビット |

| 電源要件 | 9.6 ~ 16 Vdc |

| リアルタイム クロック精度 | 年間 ±3 分 (GPS による補正はオプションです。) |

| インターネット プロトコル | FTP, HTTP, XML POP3, SMTP, Telnet, NTCIP, NTP |

| 通信プロトコル | PakBus, Modbus, DNP3, SDI-12, SDM |

| アイドル時平均消費電流 | 0.7 mA (@ 12 Vdc) |

| アクティブ時平均消費電流 |

|

| 寸法 | 24.1 x 10.4 x 5.1 cm (9.5 x 4.1 x 2 in.) |

| 重量 | 0.7 kg (1.5 lb) |

互換性

注意: 以下は代表的な互換性情報を示しています。互換性のある製品や互換性のない製品をすべて網羅したリストではありません。

Software

| 製品 | 互換性 | 注意 |

|---|---|---|

| LoggerNet | (Version 3.3 or higher) | |

| PC200W (リタイア) | ||

| PC400 | (Version 1.4 or higher) | |

| PCONNECT (リタイア) | (Version 3.3 or higher) | |

| PCONNECTCE (リタイア) | (Version 2.2 or higher) | |

| RTDAQ | ||

| Short Cut | ||

| VISUALWEATHER | (Version 2 or higher) |

互換性に関する追加情報

センサ

複数のチャンネル タイプを備えた CR800 は、熱電対、SDI-12 センサ、4 ~ 20 mA センサなど、ほぼすべてのセンサと互換性があります。カスタム ASIC チップにより、パルス カウント、Cポート、シリアル通信機能が拡張されます。CR800 の I/O ポートは送信と受信としてペアリングでき、シリアル センサやデバイスとのシリアル通信が可能です。

計測および制御周辺機器

CR800 は、当社のすべての CDM (SC-CPI が必要)、SDM、マルチプレクサ、バイブレーティング ワイヤ インターフェイス、端末入力モジュール、リレーと互換性があります。

コミュニケーション

CR800 は、直接接続、NL201 イーサネット インターフェイス、マルチドロップ モデム、電話モデム (固定電話、デジタル セルラー、音声合成)、RF テレメトリ、衛星送信機 (Argos、Iridium、Inmarsat) を介して PC と通信します。

データは、CR1000KD キーボード ディスプレイ、キーパッド付き CD100 マウント可能ディスプレイ、ユーザー提供の iOS または Android デバイス (LoggerLink が必要)、CD295 DataView II ディスプレイ、またはユーザー提供の PDA (PConnect または PConnectCE ソフトウェアが必要) で表示できます。

SC115 は、互換性のある唯一の外部データ ストレージ デバイスです。CR800 には周辺ポートがないため、CFM100、NL115、または NL120 とは互換性がありません。

屋外収納ケース

CR800 とその電源は、当社の屋外収納ケースに収納できます。

電源

12 Vdc 電源であれば、CR800 データロガーに電力を供給できます。CR800 で一般的に使用される電源は、BPALK、PS150、および PS200 です。BPALK は、20°C で 7.5 A h 定格の非充電式 D セルアルカリ電池 8 本を提供します。

PS150 と PS200 はどちらも、密封された充電式 7 A h 電池と充電レギュレータで構成されています。これらの電池は、充電源 (壁の充電器またはソーラーパネル) に接続する必要があります。これら 2 つの電源は、充電レギュレータが異なります。PS150 には標準レギュレータがあり、PS200 にはマイクロコントローラベースのスマートレギュレータがあります。PS200 のレギュレータは、2 段階の定電圧充電と温度補正を提供し、電池の充電を最適化して電池の寿命を延ばします。

また、それぞれ 12 A h と 24 A h の公称定格を提供する BP12 および BP24 電池パックも利用できます。これらのバッテリは、規制された充電源 (規制されていないソーラーパネルまたは壁の充電器に接続された CH100 または CH200 など) に接続する必要があります。

ソフトウェア

CR800 の完全なプログラミング言語である CRBasic は、単純なプログラミングや複雑なプログラミング、および多くのオンボード データ削減プロセスをサポートします。

ドキュメント

テクニカルペーパー

- Benefits of Input Reversal and Excitation Reversal for Voltage Measurements

- Preventing and Attacking Measurement Noise Problems

- Data Streaming

- Voltage Measurement Accuracy, Self-Calibration, and Ratiometric Measurements

- BACnet to Modbus Protocol Conversion (App. Note: 1M-C)

- DNP3 with Campbell Scientific Dataloggers

- Serial Sensors: Interfacing with CSI Dataloggers (App. Note Code: 2MI-V)

- FTP Troubleshooting

コンプライアンス

動画とチュートリアル

ダウンロード

CR800 OS v.32.07 (4.41 MB) 15-05-2024

Execution of this download installs the CR800 Operating System and Compiler on your computer. It also updates the CR800 support files for the CRBasic Editor.

Note: This OS has crossed the 2 Meg CR800 size limit for remote download. The OS must be downloaded to the 2 Meg CR800 via direct connect with the Device Configuration Utility. All OS download methods are supported by the 4 Meg CR800.

Upgrading from versions prior to version 28 of the Operating System will reset the datalogger’s CPU drive. This is due to a change in the format of the file system from FAT16 to FAT32. In order for the datalogger to operate correctly, as part of the upgrade, the CPU drive is formatted to FAT32. Any programs stored and running from the CPU drive will be lost. It is not recommended to update the datalogger’s Operating System over a remote connection where program control regulates the communication equipment (turning it on or off, etc.). In these cases, an on-site visit and a backup using DevConfig’s backup utility is necessary to update the datalogger’s Operating System.

Watch the Video Tutorial: Sending an OS to a Local Datalogger.

In all cases where the datalogger is being updated from an Operating System prior to 28, the use of DevConfig’s backup utility is recommended due to the CPU drive being formatted using the new FAT32 format.

Device Configuration Utility v.2.33 (49.6 MB) 07-07-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

よくある質問

CR800に関するよくある質問の数: 156

すべて展開すべて折りたたむ

-

The CPU of the data logger can be removed and mated with a different CR800 wiring panel. This can be done by removing the four corner nuts on the underside of the CR800. Do not loosen the two middle nuts. Be careful not to damage the pins mating the CPU with the wiring panel.

-

Yes, unless the CR1000 program contains measurement instructions for channels not available on the CR800 or CR850.

-

No. The setup is identical.

-

No. A device is needed that can convert fiber optic to RS-232. Many customers have used products from B&B Electronics for this purpose.

-

Yes. Many customers use the Iridium satellite transceiver.

-

The 5 V terminal is regulated and remains near 5 Vdc (±4%) as long as the CR800 supply voltage remains above 9.6 Vdc. Measurement of the output from 5 V (by means of jumpering to an analog input on the same CR800) enables an accurate bridge measurement if the 5 V terminal must be used for excitation.

-

Use the CRBasic Editor in LoggerNet or PC400.

-

LoggerNet is available in a Linux version (LNLINUX).

-

The upper limit is limited by a surge protection device on the wiring panel, which is a 1.5KE20CA. The key limit is for constant dc voltages; it starts to become leaky as the voltage increases and reaches the range of its nominal surge clamp voltage of 20 V. It is possible to damage that component if the voltage is continuously held near its clamp voltage, causing it to dissipate a lot of power.

There are also other issues of internal heat generation, which could increase measurement errors at high temperatures—especially if powering sensors or peripherals from the data logger.

This is why the limit of 16 V is quoted, which is within the normal operational voltage of lead-acid batteries. If the voltage creeps a little above this, especially when cold, it should not cause a problem.

-

No more than 30 tables are allowed.

ケーススタディ

概要 ウダムプール・シュリーナガル・バラムーラ鉄道リンク(USBRL)プロジェクトは、カシミール地方とインド全土を全天候型交通網で結ぶ国家的重要性を帯びています。現在この目的に使用されている道路網は、特に冬季に頻繁に混乱するため、この鉄道リンクはこの地域にとって待望のプロジェクトです。本ケーススタディでは、プロジェクト全体に含まれる24の橋梁のうち、橋梁39と橋梁43の2つの監視ソリューションについて説明します。 橋39 橋梁39は、全長約490メートル(1,607.6フィート)に及ぶ、高く先細りの長方形の中空橋脚を持つ、工学上の驚異です。橋脚の間隔は両端で53.15メートル(174.38フィート)、内側の5つの橋脚の間隔はそれぞれ64メートル(209.97フィート)です。この橋の上には複線式のレアシ駅構内があります。橋の上部構造は連続合成鋼桁です。 橋43 橋梁43は全長777メートル(2,549.2フィート)で、支間は35メートル(114.83フィート)、53メートル(173.88フィート)、64メートル(209.97フィート)支間10個、そして49メートル(160.76フィート)です。この橋には複線サラル駅構内があります。橋の上部構造も連続合成鋼桁です。橋長497メートル(1,637フィート)の直線部と287メートル(941.6フィート)の曲線部があります。 橋39と43 構造ヘルスモニタリング(SHM)および保守管理システム(MMS)の性能仕様は、コンカン鉄道株式会社(KRCL)のリファレンスに基づいています。SHMとMMSは、KRCLのSHMおよびMMSリファレンス設計の機能要件を維持しつつ、以下の9つの機能強化が行われています。 橋脚セグメント内の接着された内部ポストテンション(U字型垂直)緊張材の直接監視(応力とひずみ) デッキセグメント内の単純支持I桁の直接監視(応力とひずみ) 列車運行制御のための風データを用いた環境パラメータの直接監視 加速度計を使用して、高速衝撃や地震活動による橋梁への影響を監視します。 橋脚の横桁の監視 たわみ導出のための中間スパンでの強化されたひずみ監視 Campbell ScientificのSHMシステムは、KRCLリファレンスデザインの長期的な動的状態と健全性を監視します。多機能計測制御ユニットであるCR6は、橋梁監視に使用されるバイブレーティングワイヤ型センサーの中核となるデータ収集ユニット(DAQ)として使用されます。DAQは、バイブレーティングワイヤひずみゲージ、バイブレーティングワイヤ型ロードセル、温度センサー、3Dサーボ型加速度計の信号状態を収集・検出します。 SHMシステムは、CR6ユニット4台、CR1000Xユニット2台、CR800ユニット2台、VOLT116ユニット6台、そしてAM16/32B拡張周辺機器8台で構成され、合計500個以上のセンサーを計測しています。これらのDAQからのデータは、光ファイバーを介して共通制御室に伝送されています。このセンサー、データ収集、そしてデータ伝送の組み合わせは、橋梁の健全性と耐久性を確保し、必要なメンテナンスを行うための意思決定に役立ちます。 SHMデータの大部分には、200個以上のバイブレーティングワイヤセンサーによる構造ひずみとロードセルの測定データが含まれています。これらのセンサーは、Campbell Scientific CR6によって測定され、特許取得済みのVSPECT® 技術を用いてノイズのない同時データを提供します。 結論 USBRLプロジェクトは、カシミールとインド全土を結ぶ信頼性の高い全天候型輸送リンクを提供する、革新的なインフラ整備プロジェクトです。天候に左右される道路による頻繁な混乱を解消します。39番橋や43番橋といった主要橋梁にCampbell Scientific社の先進的なSHMシステムを導入することで、この重要な鉄道回廊の長期的な安全性、安定性、機能性を確保する上で極めて重要な役割を果たします。SHMシステムは、荷重、歪み、振動、環境要因、潜在的な構造的弱点を継続的に監視することで、予防的な保守と新たなリスクへの迅速な対応を可能にし、ダウンタイムを最小限に抑え、運用の信頼性を高めます。プロジェクトの進展に伴い、これらのインテリジェントな監視システムを他の橋梁にも統合することで、鉄道網全体のレジリエンスを強化し、将来にわたって途切れることのない接続性を維持していきます。...続きを読む

背景 2022 年、ECR Medio Ambiente は、以前は別のエンジニアリング会社が管理していたサグラダ ファミリア大聖堂の構造監視設備の監視責任を引き受けました。キャンベル サイエンティフィックのさまざまな機器を組み込んだ監視システムは、この象徴的な建築傑作の構造的完全性を確保することを目的としていました。 課題 この移行には、特定のセンサーとその配線を識別するという大きな課題がありました。適切なラベルと校正シートがなかったため、最初から設備の詳細な在庫と分類を維持することが極めて重要であることが浮き彫りになりました。 解決策 包括的な設備には、亀裂計、圧力セル、気象観測所、加速度計、ガス検知器などのさまざまな地質工学機器が含まれていました。さまざまな周波数でデータを収集するこれらの機器は、2008 年以来、大聖堂の構造状態を追跡する上で重要な役割を果たしてきました。ECR Medio Ambiente は、その専門知識を活用して、構造モニタリングの責任を統合し、引き継ぎました。同社は、RAD10、イーサネット アダプター (NL121)、AVW200、AM16/32、CR800、CR1000、CR1000X、WindSonic、電気キャビネット/エンクロージャなどのセンサーの正確な識別とラベル付けを確実に行う徹底した在庫および分類プロセスを実施しました。キャリブレーション シートは細心の注意を払って維持されました。 メリットと影響 構造的健全性の継続:......続きを読む

持続可能なイノベーションのための国際パートナーシップ 農業における水利用の改善は、気候変動にうまく適応するために不可欠です。FarmImpact プロジェクトでは、ドイツと南アフリカのパートナーが技術的ソリューションと生態学的アプローチを組み合わせて、南アフリカの西ケープ州におけるワインや果物の栽培の微気候と生産性に対する防風垣の影響を調査します。 南アフリカは、今後数十年で気候変動とそれが農業、ブドウ栽培、果樹栽培に及ぼす悪影響に関して、より大きな課題に直面することになります。アグロフォレストリーシステムは、農業の気候変動への適応に貢献することができます。研究プロジェクト「南アフリカのアグロフォレストリー - 変動する気候下での革新的な土地利用システムの新しい道筋」(ASAP) は、気候変動の影響への適切な対応として、農業地帯に樹木を植えることを目指しています。このプロジェクトは、ドイツ、ナミビア、南アフリカの研究機関と大学間の共同研究プロジェクトを確立するための研究プログラム「SPACES II - 南アフリカの複雑な地球システムプロセスへの適応のための科学パートナーシップ」に貢献しています。このプログラムは、地球システム管理に関する科学的推奨事項の策定に貢献し、この地域の複数の生態系サービスの持続可能な利用を確保することを目的としています。SPACES II は、ドイツ教育研究省 (BMBF) の資金提供を受けています。 農業用水の利用の調査 水不足は、気候変動の影響、人間の脆弱性、生物多様性と生態系機能の喪失とともに、南アフリカにおける最大の課題の 1 つです。特に農業は、顕著な乾期と水不足によって脅かされています。小麦、ワイン、果物の栽培の中心地である西ケープ州は、国の食糧安全保障にとって非常に重要です。これに加えて、南アフリカは長年にわたり、ヨーロッパへの農林産物の主要輸出国となっています。 ドイツ、コットブスのブランデンブルクエネルギー技術センター(CEBra)のマイク・ヴェステ博士とドイツ、ミュンヘベルクのライプニッツ農業景観研究センター(ZALF)のロジャー・ファンク博士は、南アフリカのステレンボッシュ大学植物学・動物学部のケリー・アン・グレイとガイ・ミッドグレイと共同で、ステレンボッシュ地域の柑橘類の果樹園とブドウ園における樹木と作物の相互作用を調査しています。その目的は、発見された環境上の利点を利用して、農業景観に統合する必要がある革新的で多目的な土地利用管理方法としてのアグロフォレストリーシステムの利用を支援することです。したがって、典型的なアグロフォレストリーシステムを体系的に調査し、隣接する一年生作物と永年作物の放射と熱収支に対する樹木の影響を判断します。この文脈では、個々の樹木、防風林、または小規模の森林でさえも、周囲の地表温度に好ましい影響を及ぼし、それが隣接する作物の熱とエネルギーのバランスに特に良い影響を与えます。この目的のために、Apogee Instruments......続きを読む

南アフリカ南西部では、2015年から2017年まで3年連続で乾燥した冬が続き、2018年初頭にはケープタウンで「デイゼロ」干ばつが発生しました。ケープタウンの水危機は、シャツを洗う回数を誰が一番少なくできるかを競うコンテストが行われるほどに悪化しました。レストランや企業でさえ、客や従業員に排水を減らすよう呼びかけました。この時点で、同市は水道を止めるまであと90日というところでした。 1年後、南アフリカのこの都市の干上がったダムは80%以上が満水になりました。水使用制限は緩和され、ケープタウンの市営水道が停止される「デイ・ゼロ」は到来しませんでした。この危機の回避に関する詳細は、この世界経済フォーラムの記事で確認できます。 乾燥した冬に必要となったケープタウン市は、霧の採取によってこの地域の主な水源を補う可能性を測るプロジェクトをテーブルマウンテンで立ち上げました。まだ初期段階ではありますが、このプログラムの考案者は、山に複数の霧捕集装置を建設することの実現可能性を判断したいと考えています。実現可能性調査と研究段階は、2022年12月までに完了する予定です。 このケース スタディの公開日現在、テーブル マウンテンには、基本的な気象パラメータと収集された霧を測定するための 2 つの Campbell Scientific 気象ステーションが設置されています。両方の気象ステーションには、霧から水を捕らえる、つまり「収穫」するために特別に設計された 1.5 m² (16.2 ft²) のスクリーンが装備されています。 ケープタウン市は、スクリーンに使用できるさまざまな素材のオプションをテストしています。1 つのスクリーンは 40%......続きを読む

概要 問題 バーミンガム大学は、バーミンガム市民のための教育ポータルおよび監視ステーションとして機能するため、市内に 26 の気象観測所を設置し、運用していました。時間が経ち、何年も使用された結果、これらの観測所は老朽化し、必要なデータを提供できなくなっていました。システムを最新化し、アップグレードし、保守して標準に引き上げ、市に価値を提供し続けるようにする必要がありました。 小学校、大学の敷地、自然保護区、住宅地など、さまざまな場所に設置されており、2 つのサイトが同じではないため、サービス提供に課題が生じていました。一部のステーションにはエンクロージャが欠落しており、一部の重要なコンポーネントのサービスが断続的だったため、障害やデータ不足が発生していました。 解決 Campbell Scientific はバーミンガム大学と協力し、バーミンガム市内の多数の場所にある 26 の気象ステーションを、最新の ClimaVue™50 デジタル センサー、電源供給の確実性を高める大型の SP30 ソーラー パネル、および CELL215......続きを読む

2012 年 8 月、RESPEC は、ルイジアナ州ナポレオンビル岩塩ドームの西側斜面で発生しつつある陥没穴に現場計測機器と早期警報監視サービスを提供する契約を締結しました。地下深くの塩水洞窟で構造的な亀裂が発生し、周囲の堆積物が洞窟に流れ込み、地表に陥没穴ができ、かき乱された堆積物からガスが放出されました。時間が経つにつれて、陥没穴は 40 エーカー以上に拡大し、最大深度では 400 フィートを超えました。 RESPEC のエンジニアは、発生しつつある陥没穴の周囲の傾斜と水位を継続的に監視するために、リアルタイムの早期警告システムを導入しました。陥没穴は沿岸のヒノキ沼地にあるため、監視システムは過酷な条件 (例: 猛暑、極度の湿度、ハリケーン、大雨、昆虫) で最小限のメンテナンスで稼働する必要がありました。このシステムは、Campbell Scientific のデータ......続きを読む

シルクウッド サトウキビ水質モニタリング サイトは、2014 年に「パドックからリーフまでの統合モニタリング、モデリング、報告プログラム」( reefplan.qld.gov.au ) の一環として設置されました。シルクウッド サイトは、グレート バリア リーフ集水域内の水生および海洋生態系の水質に寄与するサトウキビ作物土壌システムからの栄養素損失をモニタリングするために開発されました。このサイトはクイーンズランド州北部の湿潤熱帯地域に位置し、天然資源鉱山省によってモニタリングされています。農業慣行は MSF Sugar によって管理されています。 このプログラムはオーストラリア政府とクイーンズランド州政府が共同で資金提供しており、政府、業界団体、地域の天然資源管理団体、土地所有者、研究機関が協力して実施しています。プロジェクトの目的は次のとおりです。 施肥量や施肥形態を変えながら、サトウキビ作物土壌システムにおけるさまざまな経路で失われる窒素の量を決定する さまざまな窒素施用量と形態の試験を実施し、作物の生産と品質への影響を評価する 施用量と形態による窒素損失の違いを評価する 湿潤熱帯地域の農業生産システムからの窒素損失経路に関する現在の理解を深め、重要な損失メカニズムを特定する このサイトには、4......続きを読む

2015 年 2 月、Campbell Scientific は、ハリス郡洪水制御地区 (HCFCD) に ALERT2 システムを提供し、老朽化した従来の ALERT 洪水警報システム (FWS) をアップグレードする入札を受注しました (ケース......続きを読む

記事とプレスリリース

ブログ記事

-

How to Monitor Your Campbell Cellular Modem Data Usage: Part 2

30-01-2019 著者: Nathanael Wright -

Edlog Data Logger Support and You

05-12-2018 著者: Jacob Davis -

New Product Support: Kipp & Zonen’s RaZON+

17-01-2018 著者: Matt Perry -

Sending Email from Your Data Logger Just Got Easier!

25-01-2017 著者: Dana Worley -

Available Security Measures for Internet-Connected Data Loggers

07-12-2016 著者: Dana Worley

ニュースレター記事

- Case Study: Rain Forest Turbidity in Panama 28-10-2016

- Case Study: Hydro-SCADA System in Northern California 18-04-2016

- Case Study: Houston Transitions to ALERT2 18-04-2016

- Case Study: Geothermal Development in Colombia 02-02-2016

- Powerful New Operating System for CR800, CR1000, CR3000 04-02-2015

- New Operating System for CR800, CR1000, CR3000 17-08-2012

Privacy Policy Update

We've updated our privacy policy. 詳細はこちら

Cookie Consent

Update your cookie preferences. クッキーの設定を更新する

![データロガーのオペレーティング システム (OS) を更新する 2 部構成シリーズの第 1 部。データロガーとコンピューター間の直接接続と、デバイス構成ユーティリティの [OS の送信] タブを使用する更新方法の 1 つをデモンストレーションします。 os をローカル データロガーに送信する方法 (パート 1)](https://img.youtube.com/vi/Wm16Pjp-V2w/mqdefault.jpg)

![データロガーのオペレーティング システム (OS) を更新する 2 部構成のシリーズの第 2 部です。[接続] 画面からファイル コントロールを使用する更新方法の 1 つをデモンストレーションします。この方法は、すでに導入されていて、携帯電話や IP リンクなどの通信リンク上にあるリモート データロガーに適しています。<br /><br />

<b>重要:</b> このビデオは、シリアル番号が 7501 より大きい CR6 データロガー、CR300、または CR1000X には適用されません。 リモート データロガーへの os の送信方法 (パート 2)](https://img.youtube.com/vi/0uMY9ddZ9OE/mqdefault.jpg)